Finite Element Analysis

I've been writing FEA codes since my junior undergraduate year. Since then

I have develop a wide range of 2D/3D finite element codes for both steady

state and transient problems. Some details are given below.

2D/3D Elastostatics/Heat Conduction/Thermoelasticity

I began work on this code when I started my Master's degree program in

1995. The main focus was to produce a code that could do thermoelastic

stress analysis of internally cooled turbine blades very quickly. At that

time our group was heavily involved in a project concerning the optimization

of internal coolant passages for turbine blades. Since the optimization

code might require hundreds or even thousands of analysis calls, it was

important that each analysis take the minimum amount of computation time

possible. I spent a lot of time developing iterative sparse equation

solvers as a replacement for the direct factorizations used in many FEA

codes. Use of such iterative methods resulted in a significant improvement

in speed and much lower core memory usage. Currently, the 3D stress/thermal

analysis of a realistic turbine blade with passages takes less than one

minute on a Pentium II PC.

Some features of the code:

Sparse solvers:

-

Preconditioned Krylov subspace methods(GMRES, CG, CGS,

BiCGSTAB)

-

ILU and multilevel preconditioners

-

LU Decomposition(direct solver)

-

Cholesky Decomposition(VSS from NASA Langley)

-

Multigrid(2D) for nested and solution adapted grids

-

Uses of the Enthalpy method to handle phase change for

simulation of melting/freezing

-

Can handle unsteady heat conduction problems with

nonlinear material properties

-

High speed, automatic, suitable for optimization

-

Objected-oriented, written in C++/C/FORTRAN

-

Triangular and Tetrahedral elements with a choice of

linear or quadratic basis functions

-

Element stiffness matrices integrated analytically

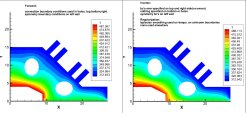

The 2D version of my code uses adaptive mesh refinement. Here's

an example for heat conduction:

Code Performance

11,000 DOF 3D Turbine Blade (Static): less than 1 min. on Pentium

200, around 15 sec. On SGI R10000

66,000 DOF 3D Turbine Blade (Static): approx. 10 min. on SGI R10000

11,000 DOF 3D Turbine Blade (Dynamic): approx. 5 min. for 100 time

steps on Pentium 200

Click on the images below to see a larger picture

3D Structural Dynamics

I also wrote an FEA code for 3D structural dynamics. Currently, this

code has not been used in any projects. It may eventually be used

for aeroelastic simulations of turbomachinery blades. Click on the

links below to see some animation of structural dynamics results produced

with my code.

Vibrating

Beam

Blade

Blade2

Blade

with Passages

Blade

with Passages 2

Inverse detection of boundary conditions in 2D thermoelasticity

I developed a finite element algorithm for the inverse detection of unknown

boundary conditions for Laplace and Navier equations. I also implemented

this algorithm in my 2D thermoelastic finite element code. Below is an

example of a forward and inverse heat conduction analysis of an annual

region with 16 internal circular cavities. In the well-posed or forward

problem, a Dirichlet boundary condition is applied on all boundaries. But

in the inverse problem, both the Dirichlet and Neumann boundary conditions

are applied to outer circular boundary while no boundary conditions are

applied to the internal cavities. The inverse FEA code is able to accurate

predict the temperature distribution throughout the entire domain, even

on the internal boundaries.

Click on the images below to see larger pictures

Well-posed(forward) and inverse analysis

|

Well-posed(forward) and inverse analysis

|

2D Incompressible Navier Stokes/Euler with LSFEM

In the spring of 1999, I began developing several 2D fluid mechanics codes

using the Least-Squares Finite Element method (LSFEM).

Advantages of the LSFEM

-

Can use equal order basis functions for pressure and

velocity

-

No free parameters to tune

-

can use the first order form of PDE’s

-

can handle any type of equation and mixed types of

equations

-

Can discretize convection terms without upwinding or

explicit artificial dissipation

-

Clean and robust method

-

Resulting system of equations is symmetric and positive

definite

-

Simple iterative techniques and multigrid can be used

to solve the system of equations

-

Easy to construct high order approximations via

P-methods

-

rigorous convergence theory exists

-

strong mathematical background

-

Always leads to a minimization problem rather than saddle point problem

(interpolation function do not need to satisfy LBB condition)

Below is an example of low speed inviscid, rotation flow (Euler equations)

over a circle computed with a finite volume based code and with my LSFEM

code. One can see that upwinding require by the FVM code for stability

creates a noticeable asymmetry in the pressure field. My LSFEM code produces

a perfectly symmetric pressure field that matches the analytic solution

obtained from potential flow theory.

Click on the image below to see a larger picture

Comparision of FVM and LSFEM for Euler flow around a circle

|

Below is an example of viscous incompressible flow though a sudden expansion

at a Reynolds number of 450.

Click on the image below to see a larger picture

Viscous flow through a sudden expansion for Re=450 |

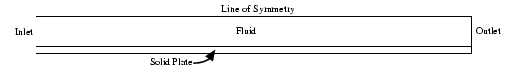

2D Magneto-Hydrodynamics with Conjugate Heat Transfer with LSFEM

Recently I have developed a 2D code to simulate magneto-hydrodynamics with

conjugate heat transfer.

This code was used to study the effect of an applied magnetic field

to the heat transfer (conductive and convective) characteristics of an

incompressible, electrically conducting fluid such as seawater.

Conjugate heat transfer problems involve the simultaneous prediction

of heat transfer in both the fluid field and the solid wall surrounding

the fluid. An example would be a cooled metal pipe carrying a hot

liquid.

In this example, a "horse-shoe" magnet is placed between the X coordinates

7 and 8. In this region, it can be see that the wall temperature

changes dramatically, depending on the strength of the magnetic field.

It can also be seen that the applied magnetic field generates a complex

vortex structure in the flow field. Also, when the magnetic Reynolds number

is high (such as when the fluid has a very high coefficient of electrical

conductivity), the interaction between the magnetic field and the moving

fluid can cause the magnetic field lines to sway in the downstream conditions.

This indicates that in MHD problems with high magnetic Reynolds numbers,

the Maxwell's equations should always be solved together with the Navier-Stokes

equations, either simultaneously or iteratively.

Click on the images below to see a larger picture

Magnetic field lines in the presence of a moving fluid with low

electrical conductivity(seawater)

Magnetic field lines in the presence of a moving fluid with low

electrical conductivity(seawater)

|

Temperatures along solid/fluid interface for various magnetic field

strengths

Temperatures along solid/fluid interface for various magnetic field

strengths

|

Vortices induced by the presence of a strong magnetic field

Vortices induced by the presence of a strong magnetic field

|

Magnetic field lines in the presence of a highly electrically conductive

moving fluid

|

2D Electro-Magneto-Hydrodynamics with LSFEM

Recently I have developed a 2D code based on LSFEM to simulate electro-magneto-hydrodynamics.

This code was used to simulate the pumping of an electrically conducting

liquid such as sea water or blood.

In the example shown here,an electric and magnetic field are used pump

an electrically conducting incompressible viscous liquid through a channel

of height 4 cm and length 40 cm. A a uniform magnetic field of .05 Tesla

is applied in the Z direction. A positive electrode is placed at

the top of the wall and a negative electrode placed at the bottom of the

wall. A potential of 50 Volts applied across the electrodes.A parabolic

velocity profile was specified at the inlet and a pressure of 1 Pa was

specified at the outlet. The inlet temperature was 311 K and the wall temperature

was 300 K

This is a steady state calculation(no time derivatives).

Click on the images below to see a larger picture

Computed electric potential

|

Computed velocity vectors |

Computed static pressure |

Computed static temperature |

One can see from the above images that the application of a crossed electric

and magnetic field results in a pressure increase from the channel inlet to

outlet. Without either field, the pressure would decrease from inlet to

outlet due to the viscosity of the liquid. The Joule heating of the

liquid(due to the flow of electric current through the liquid) can also be seen.

2D Electro-Magneto-Hydrodynamics with p

-version LSFEM

Recently I have developed a 2D code based on p-version LSFEM to simulate

electro-magneto-hydrodynamics. This code was used to simulate the solidification

of silicon crystals with and without an applied magnetic field.

The p-version LSFEM was implemented using hierarchical basis

functions based on Jacobi polynomials. The hierarchical basis leads to a linear

algebraic system with a natural multilevel structure that is well suited to

adaptive enrichment. The sparse linear systems were solved by either direct

sparse LU factorization or by iterative methods. Two iterative methods were

implemented in the software, one based on a Jacobi preconditioned conjugate

gradient and the another based a multigrid-like technique that uses the

hierarchy of basis functions instead of a hierarchy of finer grids. The method

was implemented in an object-oriented fashion using the C++ programming

language. The software has been tested against analytic solutions and

experimental data for Navier-Stokes equations and for channel flows through

transverse electric and magnetic fields, for shear-driven cavity flows,

buoyancy-driven cavity flows, and flow over a backward-facing step.

In the example shown here, a crucible for the production of silicon crystals is simulated with and without an applied uniform magnetic field in the vertical

direction. The magnetic field strength is 1 Tesla.

This is a steady state calculation(no time derivatives).

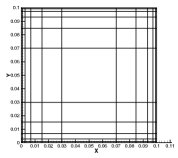

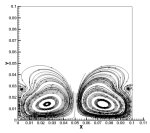

Click on the images below to see a larger picture

|

Computational mesh |

Computed streamlines with no magnetic field and

microgravity (1% of full gravity) |

Computed streamlines with no magnetic field and full gravity

Computed streamlines with no magnetic field and full gravity

|

Computed

streamlines with magnetic field and full gravity |

One can see from the above images that the application of

uniform magnetic field in the vertical direction can significantly alter the

flow field melt region of the crucible.

The computational results indicate significantly different flow-field

patterns and thermal fields in the melt and the accrued solid in the cases of

full gravity, reduced gravity, and an applied uniform magnetic field. Although

the magnetic field significantly reduces the velocity of the flow within the

melt, the crystal may still be slightly contaminated.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()