In this project we consider the optimization of the airfoil stack line for a 3D gas turbine stator blade. The VKI airfoil was choosen as the base airfoil shape. The stack line describes the circumferential position of the VKI airfoil as a function of radial position. The VKI airfoils were stacked from root to tip according to the shape of the stack line. Different stack line shapes result in different blade shapes. The goal here is to find the shape of the stack line that will result in the most efficient blade for a fixed airfoil shape. In this case, the most efficient blade is considered to be the blade with the lowest total pressure loss.

I used my PGA code to perform the optimization along with a 3D transonic finite difference CFD code provided by Eun-Seok for each function analysis. The stack line was parameterized with a b-spline with 5 control points. Each variable was discretized with a 6-bit binary string. A population of 31 was used with a 6% probability of mutation and a 50% probability of uniform crossover. The optimization was run for 20 generations on our 32 processor parallel computer. The optimization required just over 3 days of computer time.

The best design achieved after 20 generations has a total pressure recovery

coefficient of 94.7. As a comparison, a blade with a straight stack

line has a total pressure recovery coefficient of 91.6. The optimized and

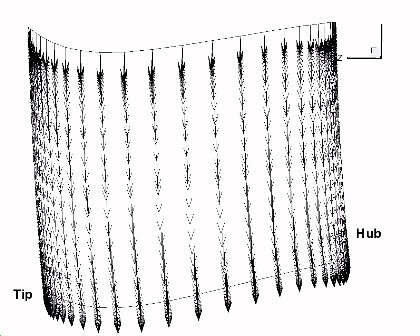

straight blade shapes can be seen in the figures below.

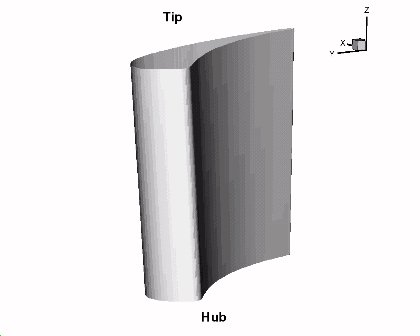

Initial straight blade |

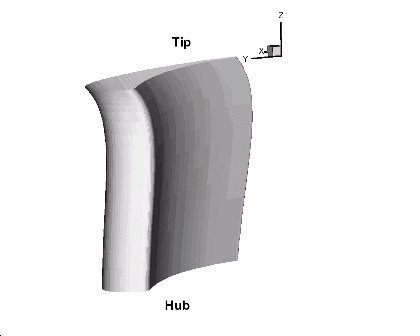

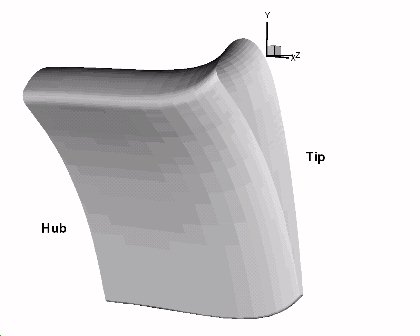

Optimized blade |

Optimized blade |

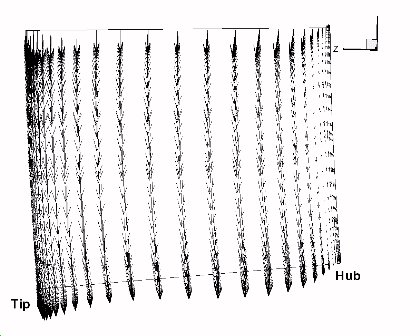

It seems that bowing the blade toward its pressure side increases its efficiency by 3% compared to a straight blade. The physical explanation for this improvement can be seen in the figures below. For the straight blade a large vortex exists along the hub wall at the flow outlet. These vortices near the hub and tip are well known sources of total pressure loss for annular stator blades. However, this vortex along the hub wall is not present for the optimized blade. The elimination of this vortex results in a significant improvement in efficiency.

Velocity vectors for flow at the outlet for straight blade |

Velocity vectors for flow at the outlet for optimized blade |

![]()